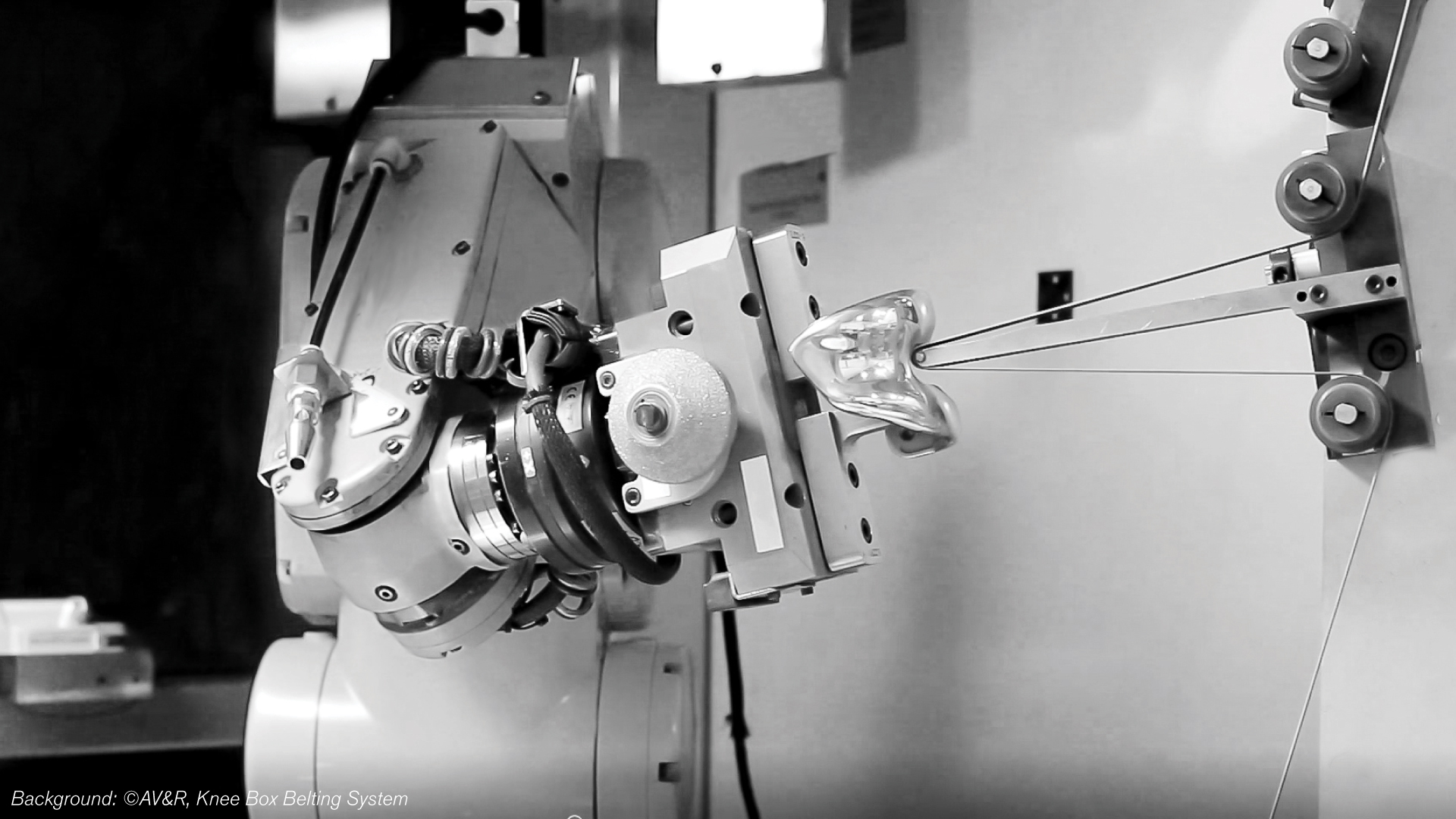

GPA Azimatronics expands partnership with Hypertherm Associates with robotic software

For the past two years, GPA Azimatronics has been working with Robotmaster® software to provide cutting-edge robotic programming solutions for cutting and welding applications.

Weiterlesen

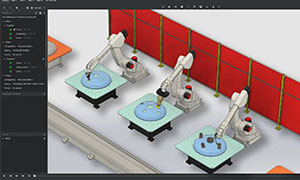

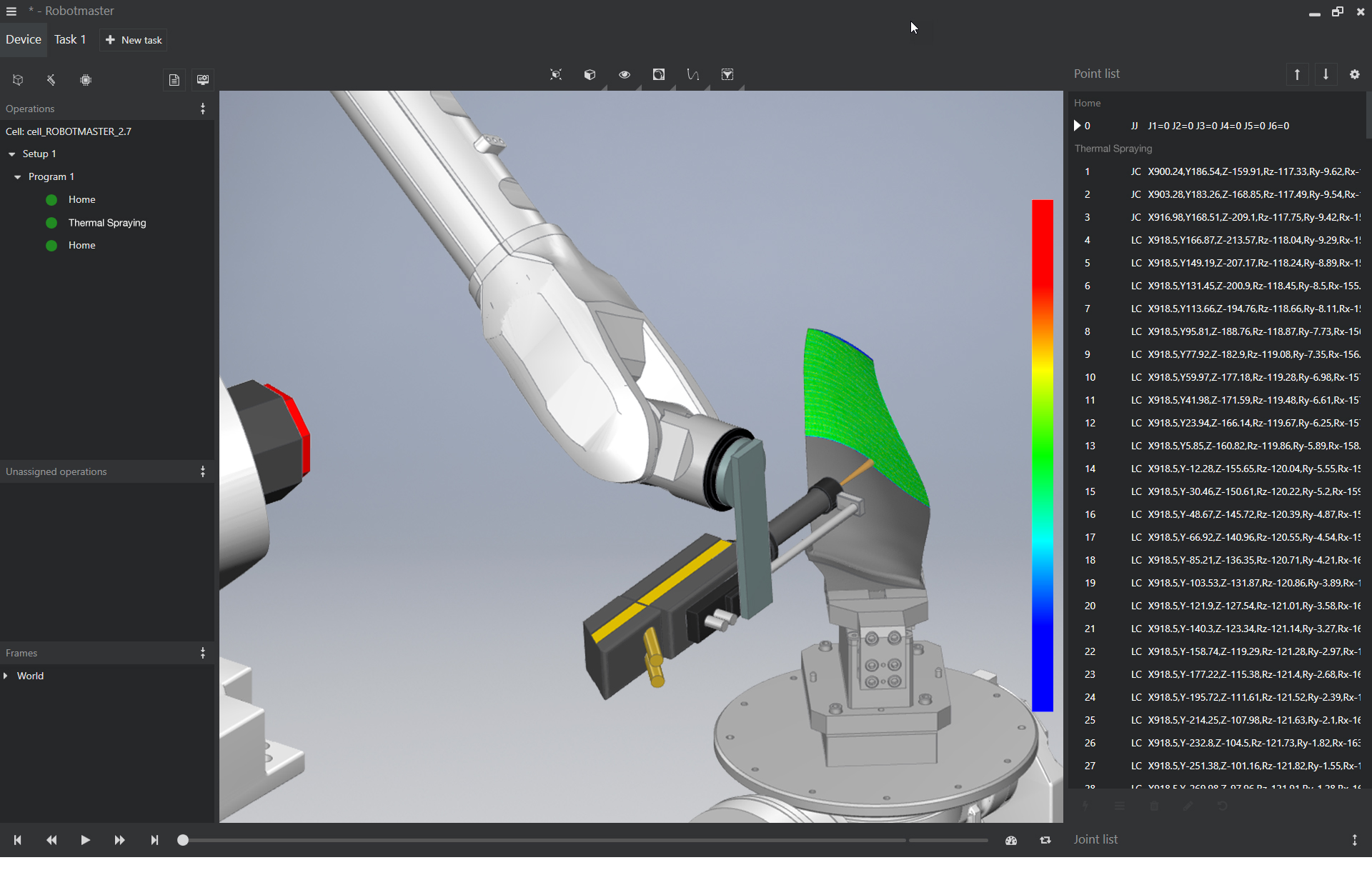

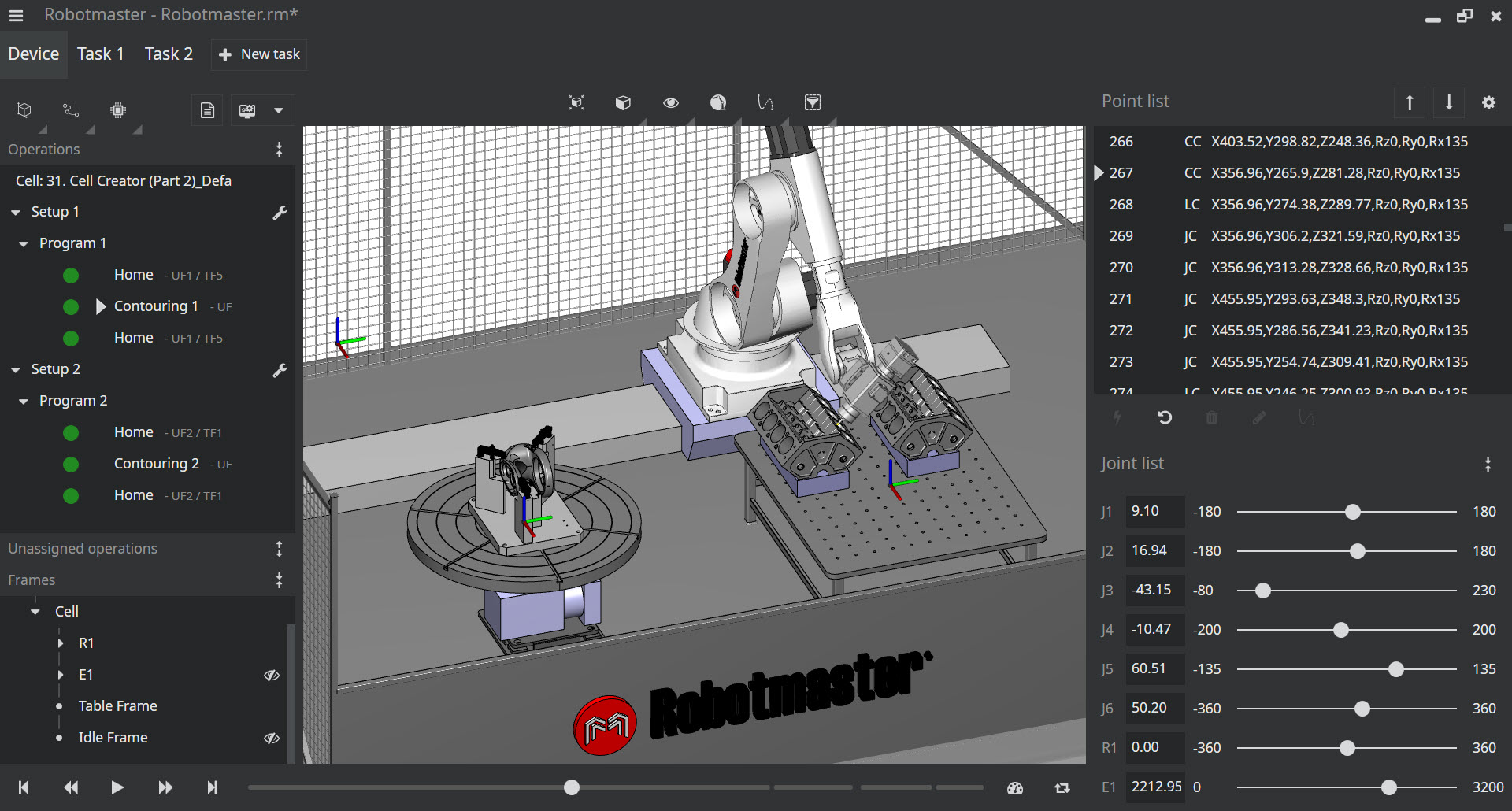

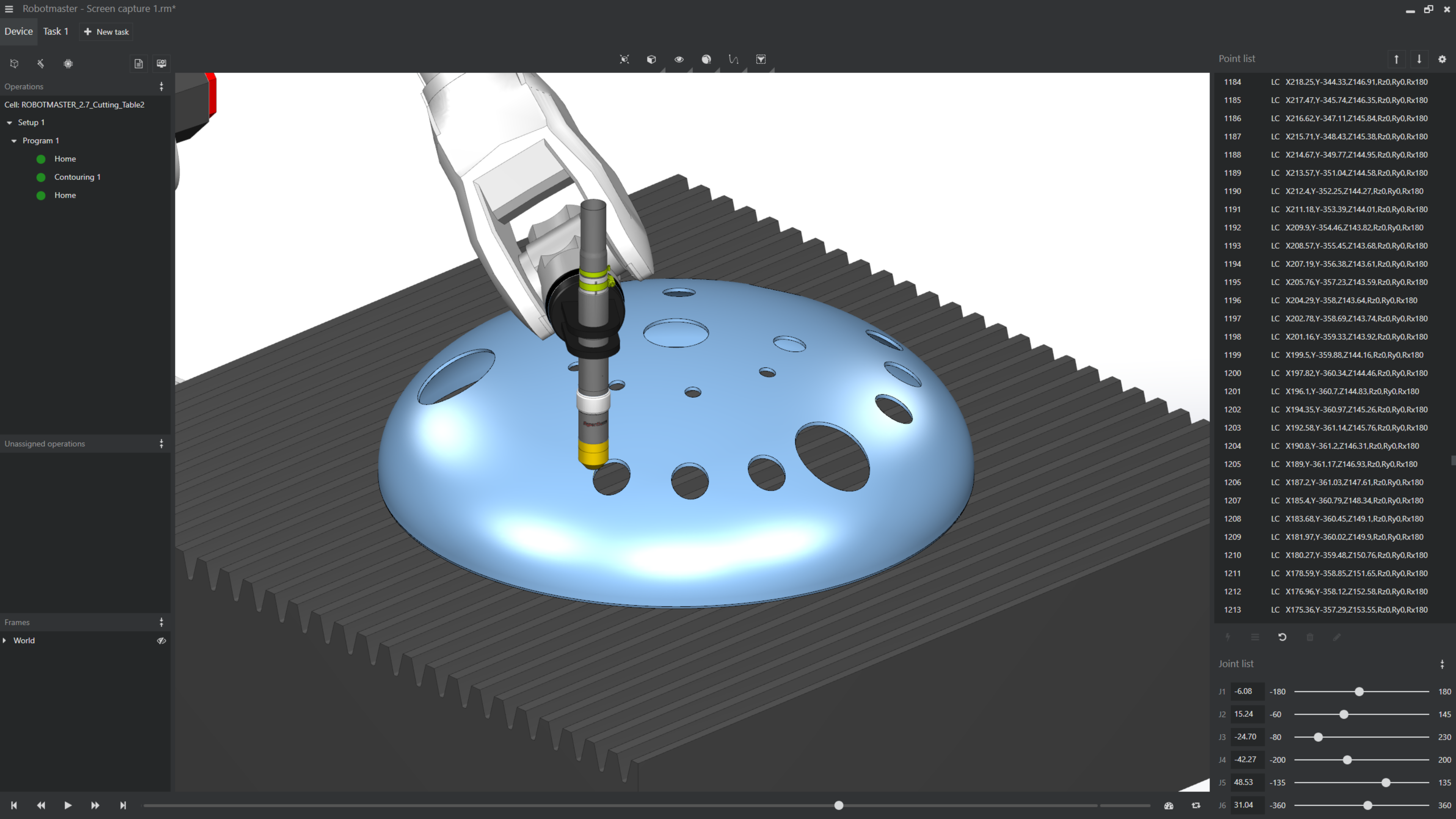

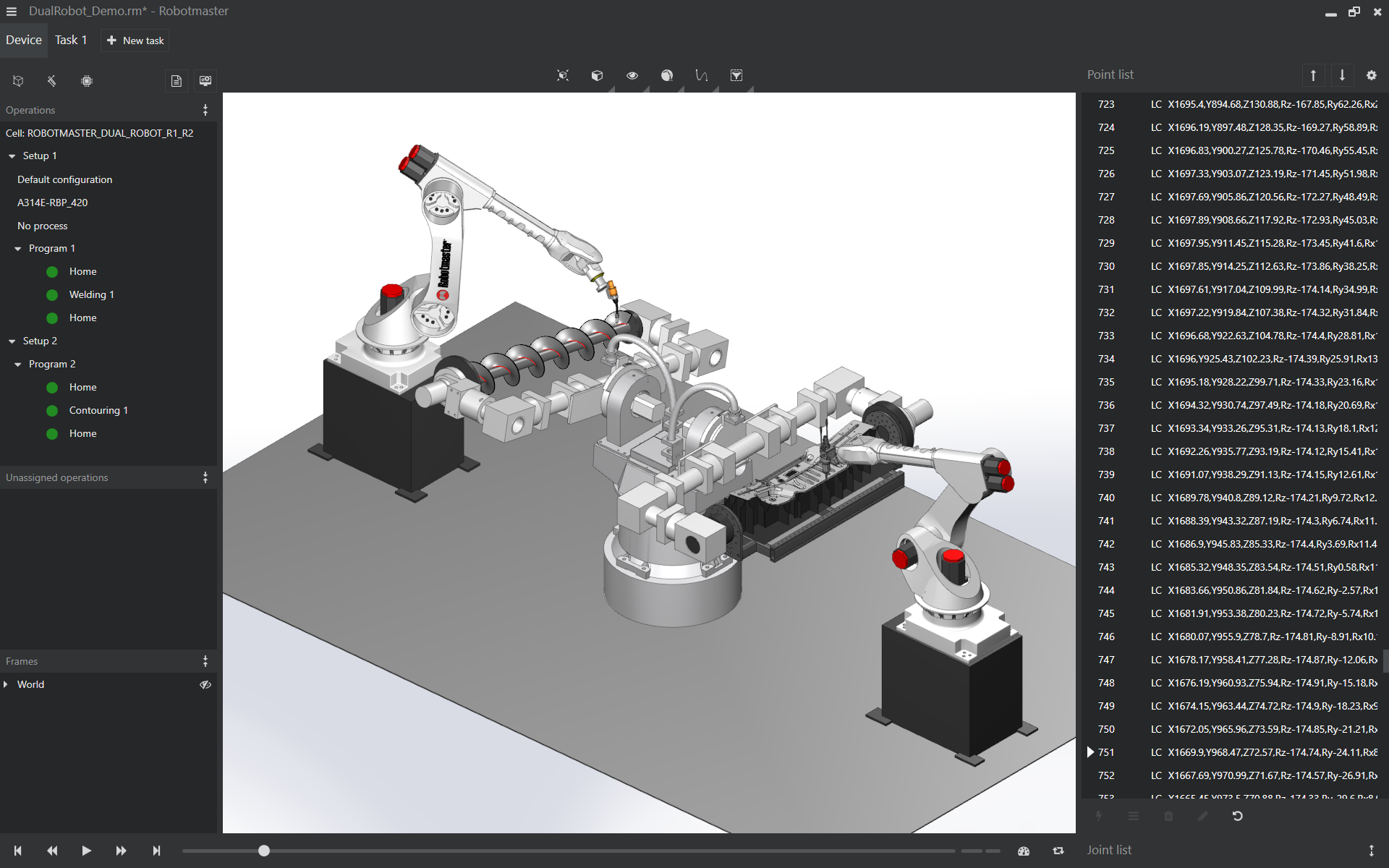

Hypertherm Associates addresses key market trends with the latest version its robotic offline programming software, Robotmaster 2024

Addressing key market trends, Robotmaster 2024 supports programming multiple robots in a single work cell and meets the demand for automatic trajectory optimization and robotic error correction.

Weiterlesen

eBook: Achieving Standardization in Robot Programming

Are you tired of spending countless hours programming your robots? Are you confused by the lack of standardized programming languages? Do you wonder if there is a better way to program all your robots? Look no further, as this eBook has all the answers you need!

Weiterlesen

Hypertherm Associates announces Sofos Robotics Co. as new authorized partner for Robotmaster offline programming software

Hypertherm Associates, a U.S.-based manufacturer of industrial cutting systems and software, today announced a new partnership for its Robotmaster ® offline programming software for robots

Weiterlesen

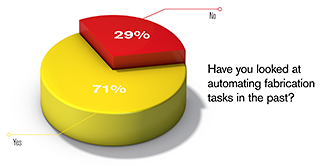

Have you looked at automating fabrication tasks in the past? Why didn’t you?

January 11, 2023 - We recently hosted a webinar titled: “Unlock Value-Stream Productivity with Robotic Cutting”. This webinar provided an overview of the latest cutting market trends and looked at some of the challenges fabricators face.

Weiterlesen

New Robotmaster plugin streamlines robotic programming for Mastercam CAD/CAM software users

January 10th, 2023 - Hypertherm Associates, a U.S. based manufacturer of industrial cutting products and software, today announced a new software plugin from its Robotmaster® brand.

Weiterlesen

Hypertherm Associates to formally close down its legal entity in Russia

November 1st, 2022 - Hypertherm Associates, a U.S. based manufacturer of industrial cutting products and software, today announced plans to formally close its legal entity in Russia.

Weiterlesen

4 Common Robot Programming Challenges

October 18, 2022 - When manufacturers are looking at transitioning their manual, labor-intensive applications to automation, a common concern that comes up is how the robot will be programmed.

Weiterlesen

3 benefits of working with a robotic integrator

September 19, 2022 - A robot or system integrator is a company that will understand the end customer’s needs, propose a design solution, and get the system up and running. Because there is more to automation than selecting a robot, working with a robot or system integrator can be extremely valuable to ensure the full robotic system is properly designed to achieve the desired results.

Weiterlesen

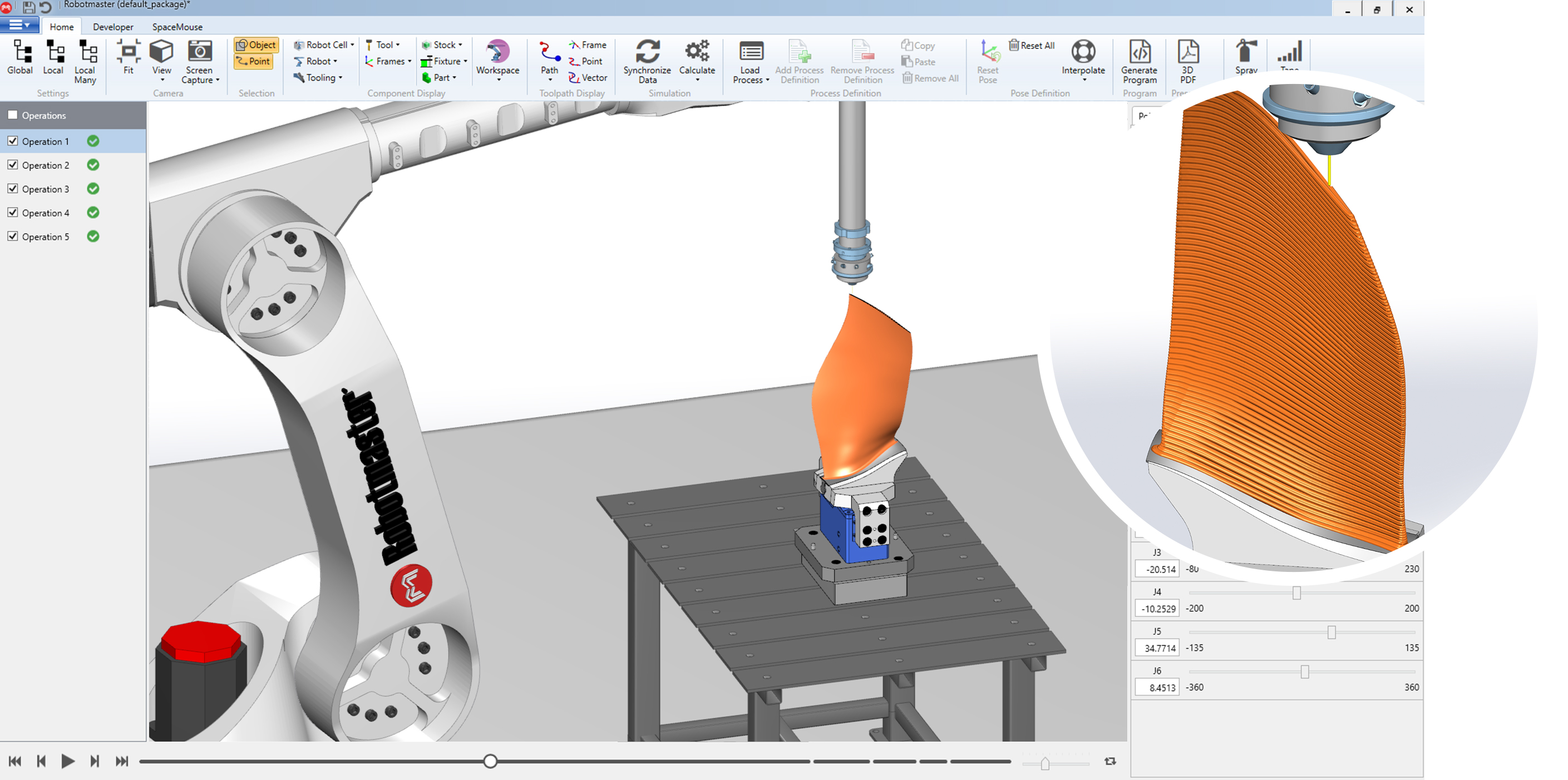

Robotmaster 2023 now here!

August 29th, 2022 - Hypertherm Associates bridges the gap between CAD/CAM and robotics with major update of its Robotmaster offline programming software

Weiterlesen

Rolph Goes Offline

July 19, 2022 - Meet rOLPh, and his operator Steve! Learn how they’ve come up with an exciting new way to work together to improve productivity and reduce downtime!

Weiterlesen

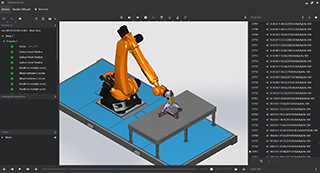

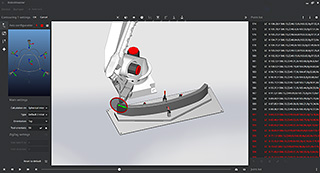

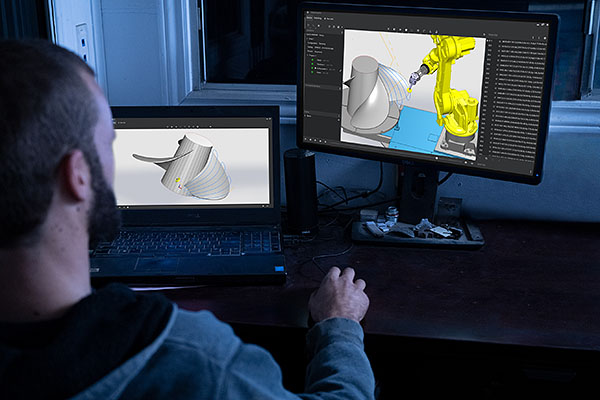

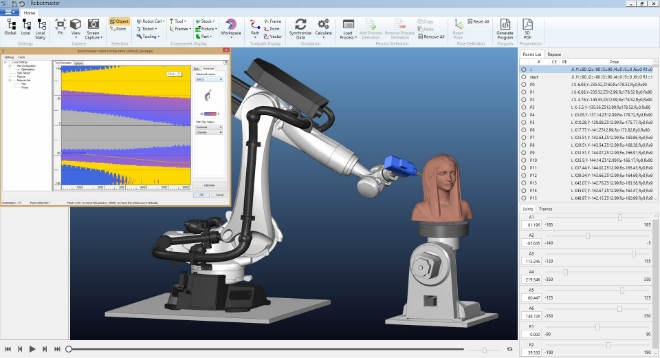

How simulation enhances the offline programming experience

May 12, 2022 - One of the strengths of offline programming (OLP) software is that it combines two powerful capabilities: simulation and programming. These two capabilities fit together like two perfect puzzle pieces when it comes to effectively programming robots offline.

Weiterlesen

Hypertherm's OMAX and Robotmaster head to Chicago for IMTS 2022

May 5, 2022 - Hypertherm's Robotmaster Team will demonstrate the latest version of its offline programming software for robots.

Weiterlesen

More process knowledge, better robotic plasma cutting

Metal fabricators across the industry—in job shops, heavy machinery, shipbuilding, and structural steel—strive to meet demanding delivery expectations while exceeding quality requirements. They look continually for cost reductions, all while dealing with the ever-present issue of retaining skilled labor. The business isn’t easy.

Weiterlesen

Hypertherm's Robotmaster to exhibit at Automate 2022

March 22, 2022 - The company's robotic software team will provide live demonstrations of its Robotmaster® offline programming software for robots from Booth 2013 at Detroit's Huntington Place Convention Center.

Weiterlesen

Why are you still manually programming your robot?

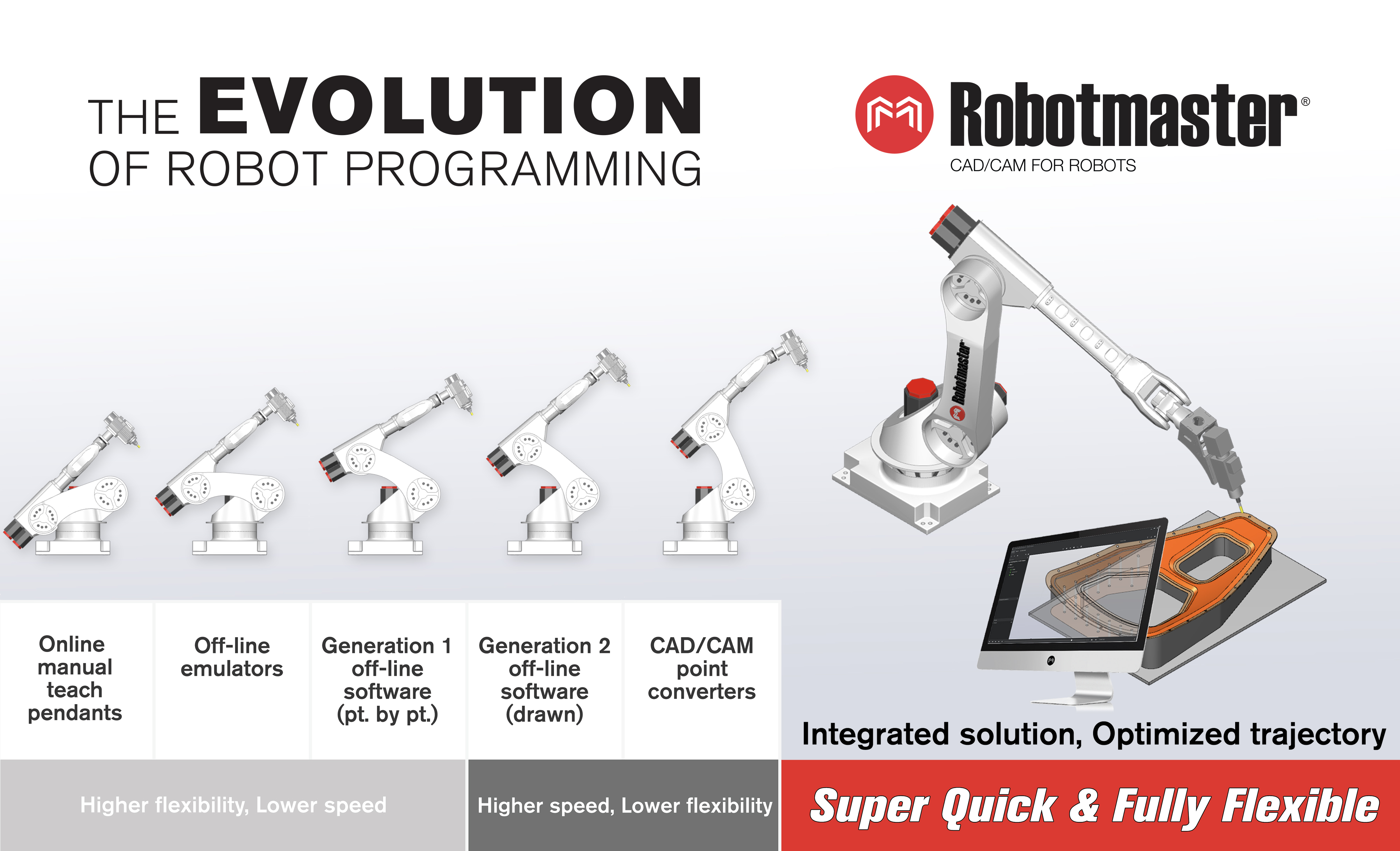

March 9, 2022 - The vast majority of jobs are still programmed manually. However, new offline robot programming (OLP) tools are rapidly changing and being adopted.

Weiterlesen

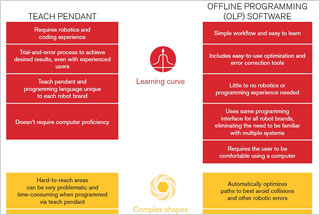

How do I know if offline programming software is right for me?

February 23, 2022 - Over the years, industrial robots have been subject to several programming methods. The two most prominent are manual teach pendant programming and offline programming (OLP) software.

Weiterlesen

Using technology to combat the skilled labor shortage

February 1, 2022 - Successful manufacturing companies are combatting the skilled labor shortage by investing in automation and software to complement their existing workforce, meet production requirements, and attract new talent.

Weiterlesen

Big Trends in Offline Programming Software for Robot: Versatility

November 8, 2021 - In the world of robotics, Offline Programming (OLP) has come a long way in a short time, and the global pandemic has jumpstarted more innovation. Industrial robots have evolved from complex assembly line robots to collaborative robots (“cobots”) that work side by side with their human counterparts. As technology advances, the industry is seeing many changes and enhancements to OLP. The first future trend we will examine is versality.

Weiterlesen

Big Trends in Offline Programming Software for Robot: Smart Machines

November 8, 2021 - As IIoT and machine learning become more sophisticated and user-friendly, users want robots with machine and robot intelligence embedded into the operating systems. This article is part two of four and explores how technology advances like smart machines is impacting the robotics and OLP world.

Weiterlesen

Big Trends in Offline Programming Software for Robot: Simplicity, Accessibility, and Simulation

November 8, 2021 - How are technological advances impacting the robotics and offline programming world? They are pushing for simplicity, accessibility, and simulation capabilities. This article is part three of four exploring some of the big trends in offline programming software.

Weiterlesen

Big Trends in Offline Programming Software for Robot: Achieve Competitive Advantages

November 8, 2021 - OLP and robot integration has become a competitive market, requiring participants to innovate to maintain their competitive advantage. This article explores how offline programming software can help manufacturers maintain a competitive advantage.

Weiterlesen

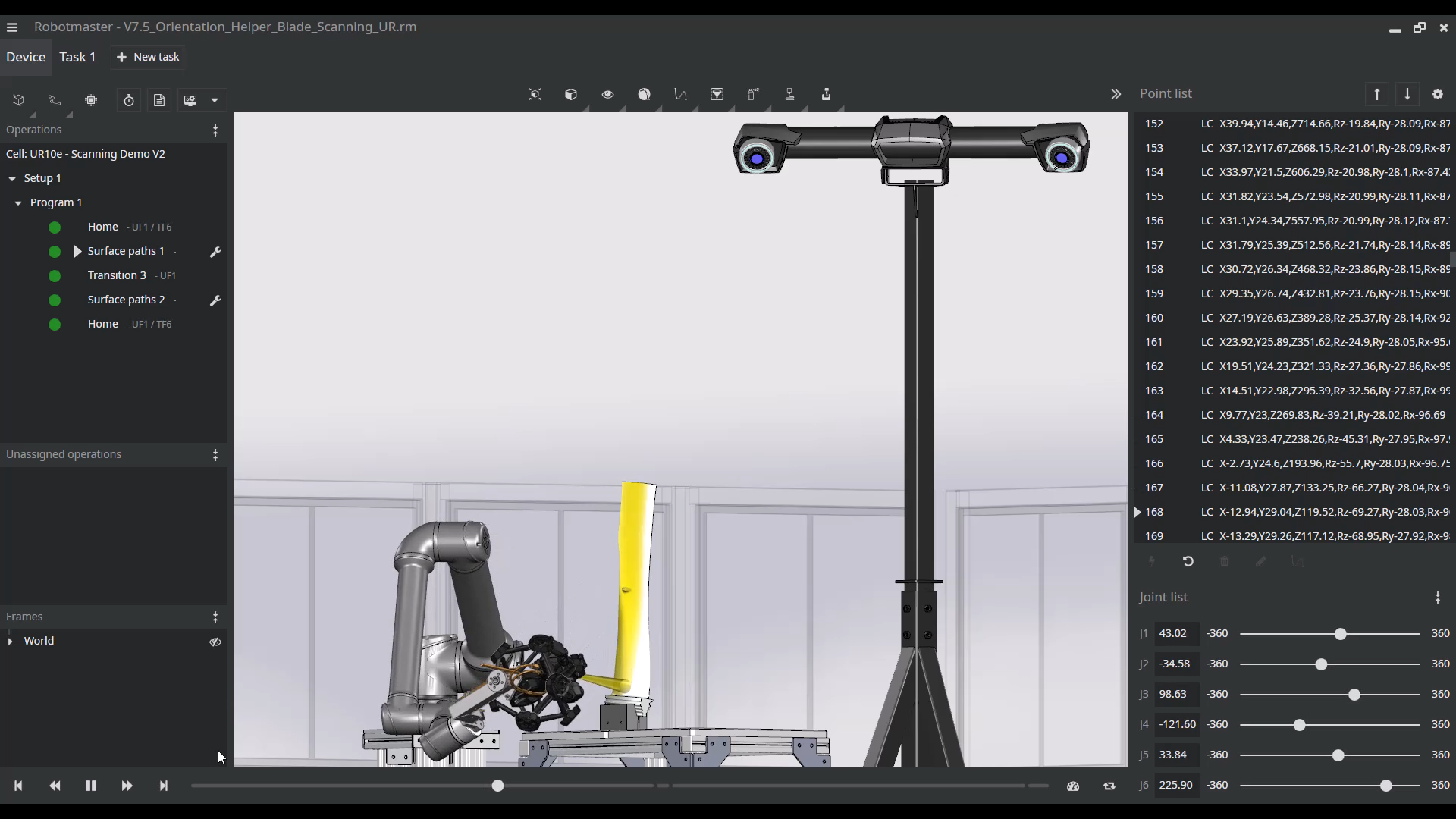

Robotmaster version 7.5 now released!

October 6th, 2021 - Program your robot faster than ever with Robotmaster’s latest update

Weiterlesen

Robotmaster Exhibiting at CMTS 2021

September 23, 2021 - Robotmaster will be exhibiting at CMTS 2021 this year from October 4 - October 7 at The International Centre in Toronto, Canada.

Weiterlesen

10 things to consider when exploring Offline Robot Programming software solutions

August 10, 2021 - Programming your robot via teach pendent can be very time consuming and inefficient. Here are 10 things to consider when exploring offline robot programming (OLP) software solutions.

Weiterlesen

Calculating the ROI of Offline Robot Programming Software

July 29, 2021 - Calculating the ROI of Offline Robot Programming Software

Weiterlesen

Why use Offline Robot Programming Software and how to get started

June 10, 2021 - Why use Offline Robot Programming Software and how to get started

Weiterlesen

Robotmaster V7.4 Now Available

March 10, 2021 - Major version update of Robotmaster robotic software now available!

Weiterlesen

Robotic Plasma Cutting in a 3D World

November 23, 2020 - A deep dive into how ARC Specialties designed and built a turnkey solution for 3D robotic plasma cutting with the help of essential offline programming tools. With the right partners by your side, no challenge is too steep.

Weiterlesen

Robotmaster V7.3 Now Available

September 10, 2020 - Major version update of Robotmaster robotic software now available!

Weiterlesen

Robotmaster V6.9 is Now Available

July 1, 2020 - The Power of Robotmaster, Taken Further. Robot Programming has never been faster, easier, and more efficient.

Weiterlesen

Robotmaster V7.2 is Now Available

May 6, 2020 - Another monumental leap forward in Robotic Programming!

Weiterlesen

ARE YOU STILL MANUALLY TEACHING YOUR ROBOT(S)?

February 11, 2020 - Say goodbye to headaches caused by using simulation software that doesn't take any and all robotic errors into account before you run the simulation!

Weiterlesen

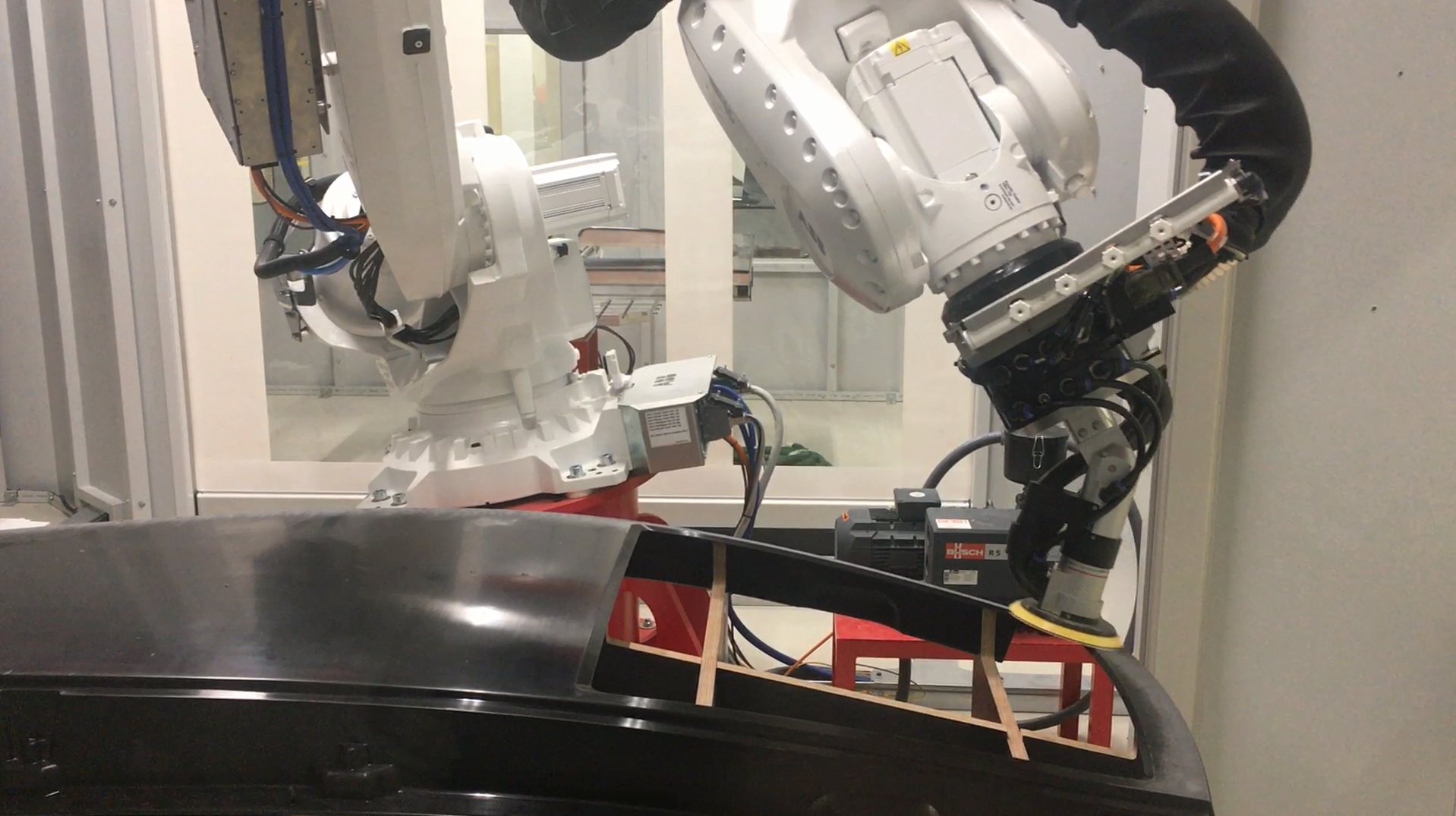

Robot Programming Platform Conquers Complex Parts Outperforms the Competition

January 22, 2020 - A plastic fabricator needed a robot programming software to handle part variety and complexity for sanding, trimming and spraying with different robot brands. After an exhaustive study of major suppliers, only one platform rose above the rest – Robotmaster offline programming software. See the new case study!

Weiterlesen

Webinar on the Revolution of Robotic Offline Programming

September 27, 2019 - The Robotic Industry Association (RIA) will be hosting a webinar given by associates from Hypertherm Robotic Software, Robotmaster on Tuesday, October 1, 2019 from 12pm - 1pm EST. Register for free!

Weiterlesen

Robotmaster Exhibiting at EMO 2019

September 13, 2019 - Robotmaster will be displaying its latest revolutionary technology this year at EMO 2019 in Hannover, Germany.

Weiterlesen

Robotmaster Exhibiting at CMTS 2019

September 25, 2019 - Robotmaster will be exhibiting at CMTS 2019 this year from September 30 - October 3 at The International Centre in Toronto, Canada.

Weiterlesen

Another Leap Forward in the Revolution of Robotic Programming

August 15, 2019 - Robotmaster has released the latest major software update, Robotmaster Version 7.1!

Weiterlesen

Robotmaster at New York Automation & Robotics Conference

Robotmaster (Hypertherm Inc.) will be present at the New York Automation & Robotics Conference on Monday, October 23, 2017.

Weiterlesen

Robotmaster V7 Exploits the Full Capabilities of Any Robotic Cell

July 19, 2018 - Criteria-Based Optimization Provides Unmatched Flexibility and Configurability

Weiterlesen

Robotmaster Improves Process Safety During Rail Maintenance

When two kilometers per hour is a high speed.

Weiterlesen

New Robotmaster V7 Reinvents Task Based Robot Programming

Revolutionary Architecture Delivers Error-Free Paths with One Simple Click

Weiterlesen

New Architecture Unveiled in Robotmaster V7 Offline Robot Programming Launch

May 31, 2018 - Offline programming software is single solution for robotic hammer peening of automotive stamping dies.

Weiterlesen

Robotmaster at Automate 2017

Hypertherm Inc. will be exhibiting at Automate 2017 which will be held April 3-6 at The McCormick Place in Chicago Illinois.

Weiterlesen

Robotmaster at FABTECH 2016

Robotmaster will be exhibiting at Fabtech 2016 which will be held November 16-18 at the Las Vegas Convention Center in Las Vegas Nevada.

Weiterlesen

Robotmaster Collaborates with Brazil's First Mobile Training Center for Robotics

**MONTREAL, July 5, 2016** – Hypertherm Inc., developer of Robotmaster programming software, together with its Brazilian distributor, RobotM-Br, is collaborating with the Instituto Avançado de Robótica (I.A.R.) in a pioneering initiative to take robotics training on the road in Brazil.

Weiterlesen

Robotmaster Dramatically Changing Construction Timber Industry

**Montreal, QC—Dec. 17, 2015** - The BBC showed how Robotmaster is dramatically simplifying the complex milling processes that architecture students need to turn firewood quality timber into high quality construction timber.

Weiterlesen

Robotmaster unveils suite of specialized software tools following FABTECH 2015

Hypertherm’s Robotic Software Team is fielding a record number of inquiries for its Robotmaster offline programing software following this month’s FABTECH trade show in Chicago.

Weiterlesen

Robotmaster Reduces Outsourcing Increases Production and Profitability

Adding a robotic system enabled Groupe Gravel, a metal fabricator, to profitably automate cutting and welding for high-mix short-batch production. Robotmaster's tools enabled automatic path creation from CAD models drastically improved programming time.

Weiterlesen

Hypertherm expands robotic capabilities with purchase of Jabez Technologies, creators of Robotmaster Software

**HANOVER, N.H.—July 30, 2015—** Jabez Technologies, creators of software to simplify complex robotic programming, is joining Hypertherm, a U.S. based manufacturer of plasma, waterjet, and laser cutting systems, to make it easier for companies to utilize robots for manufacturing applications.

Weiterlesen

Robotmaster featured in Global Business Report editorial, Automation: Revolutionizing Aerospace

President, Chahe Bakmazjian, discusses the emergence of robots and how Robotmaster enables manufacturers within the aerospace industry seeking to automate their manufacturing processes.

Weiterlesen

University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) using Robotmaster to help students’ racing team

The latest article from the Advanced Manufacturing Research Centre (AMRC) entitled, “AMRC lends a hand to Sheffield students’ racing team.”

Weiterlesen

Robotmaster Asia Leads The Robotic Revolution at Beijing Essen Welding & Cutting 2015

Montreal, CANADA and Shanghai, CHINA, July 2, 2015 – From June 16th – 19th, Robotmaster impressively underpinned its visionary position at the Beijing Essen Welding & Cutting Fair (BEW).

Weiterlesen

Robotmaster Featured in 2015 Québec Aerospace Report!

The company’s President, Mr. Chahe Bakmazjian, discusses the emergence of robots and how Robotmaster enables manufacturers, within the aerospace industry, that are seeking to automate their manufacturing processes. Many thanks to Global Business Reports for their time and efforts.

Weiterlesen

RobotM-Br Reinforces the Growing Presence of Robotmaster in Latin America at Feimafe 2015

Thousands of people attended Feimafe 2015 at the Anhembi Exhibition Pavilion from May 18 – 23 to gain insight, best practices, and key learning’s into the world of machine tooling and manufacturing.

Weiterlesen

Robotmaster now supporting Nachi brand of robots

Robotmaster (Jabez Technologies), a leader in offline programming software for robotics, today announced that it is now supporting Nachi-Fujikoshi Corporation’s NACHI robots.

Weiterlesen

Robotic Composite Manufacturing & Trimming

Singularity, calibration, collisions, reach limitations, and motion granularity are uniquely complex to robotic systems and can make programming particularly cumbersome.

Weiterlesen

Robotmaster Enhances Integrated Workflow Capabilities with New Features for Robotics Users

Robotmaster (Jabez Technologies) today announced the launch of the latest version of its leading robotic programming software, offering enhanced design and usability along with several new feature sets.

Weiterlesen

Robotmaster (Jabez Technologies) recognized as 20 Most Promising Robotics Solutions Providers for 2015!

Jabez Technologies (developers of Robotmaster) is featured in the April 2015 issue of CIO Review. The company was also recognized as one of the 20 Most Promising Robotics Solutions Providers for 2015. Jabez Technologies was selected for companies that are the forefront of providing robotics technology solutions and impacting the marketplace signature.

Weiterlesen

Robotic programming brings increased productivity and faster return on investment

Robotic automation solutions help manufacturers increase their productivity, through a reduction of inputs like energy requirements or production errors, while improving production output, produce quality and consistency. An article entitled, “Robotic programming brings increased productivity and faster return on investment”, was put together thanks to our distributor in Brazil.

Weiterlesen

Robotmaster at Automate 2015

Jabez Technologies will be exhibiting at Automate 2015 at McCormick Place in Chicago, IL from March 23rd – 26th! Come and meet with us at Booth #270 to hear more about our robot programming technologies!

Weiterlesen

Robotmaster Discussed in RIA Article

The latest article from the Robotic Industries Association entitled Robotics in 2015 and Beyond, features a section about 3D-printing robots and a discussion with president of Robotmaster (Jabez Technologies), Chahe Bakmazjian.

Weiterlesen

Robotmaster is proud to announce that Golden Robot has become the first authorized distributor of Robotmaster in Thailand

Jabez Technologies is pleased to announce that Golden Robot has become the first authorised distributor of Robotmaster in Thailand.

Weiterlesen

Intuitive Robot Programming for Flexible Aerospace Manufacturing

Robots are proving to be flexible tools for aircraft manufacturing and assembly. Their full potential, however, can be limited by the challenges of programming a robot in a CAD/CAM environment. Software that integrates offline programming, simulation, code generation, and path optimization makes the process seamless and error-free.

Weiterlesen

Robotmaster 6.2 Software Features New Integrated Workflow

New Robotmaster version 6.2 software will be at least three times faster than previous models.

Weiterlesen

Robotmaster at AUTOMATICA 2014

Robotmaster will be exhibiting at AUTOMATICA, the International Trade Fair for Automation and Mechatronics that runs from June 3 to 6 2014 in Munich (Germany). Come visit us at Hall B4, Stand 307 and ask for a demo of Robotmaster.

Weiterlesen

Jabez Technologies makes the cover of CIO Review Magazine

Jabez Technologies (developers of Robotmaster) makes the cover of CIO Review Magazine and gets recognized as one of the 10 Most Promising Engineering Solution Providers for 2014. Jabez Technologies was selected for successful implementation of CAD/CAM software for elevating the performance of the robotics industry allowing manufacturers to seamlessly interact with robots through a new intuitive programming interface.

Weiterlesen

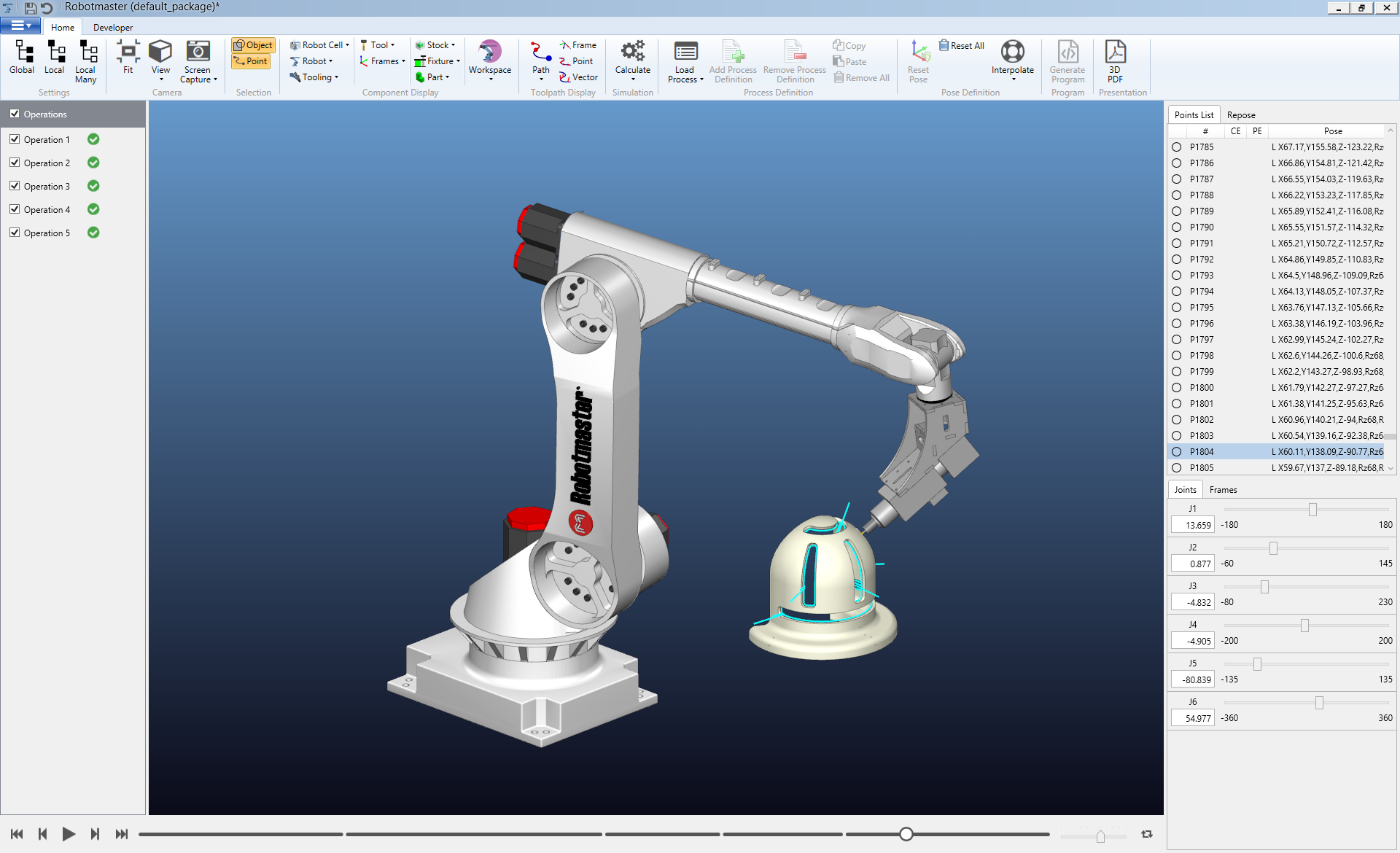

Jabez Technologies has just released Robotmaster V6.1

Jabez Technologies has just released Robotmaster V6.1. Building on the Robotmaster Interactive Simulations Environment introduced in 2013, V6.1 provides exciting new features and enhancements developed specifically for high-mix low-volume robotic applications.

Weiterlesen

Jabez Technologies wins Game Changer Awards

ROBOTMASTER V6 seamlessly integrates robot programming, simulation and code generation inside CAM software, delivering quicker robot programming. Unlike existing solutions that depend on either manual point-by-point programming or sub-optimal, hit-or-miss automation, ROBOTMASTER leverages mature CAD/CAM techniques to automate generation of optimized trajectories.

Weiterlesen

Jabez Technologies has just released Robotmaster V6

Jabez Technologies has just released Robotmaster V6 providing a unique integration of user control, speed and flexibility to Robotmaster's renowned automation and optimization tools. The new and intuitive V6 interface elevates Robotmaster to an unprecedented standard of user experience by giving robot programmers a coherent and dynamic tool that radically saves time and money.

Weiterlesen