New Robotmaster V7 Reinvents Task Based Robot Programming

Revolutionary Architecture Delivers Error-Free Paths with One Simple Click

You shouldn’t need an advanced education to program a robot. With hardware advances in robotics there has been a correlated improvement in software capabilities that have far surpassed the tedious process of point-by-point programming. But now with Robotmaster’s monumental new platform, you’re just one click away from error-free task-based programming.

Manufacturing is changing and technology must keep pace. Mass customization, shorter production runs and smaller lot sizes challenge traditional automation methods. Today, the implementation of automated manufacturing processes must be as dynamic as the market. Robot programming must be equally agile.

“If you have long production runs that last months or a year, you can afford a two-week programming cycle,” says Garen Cakmak, Senior Director at Hypertherm Robotic Software, makers of Robotmaster offline programming software. “You can’t tolerate those delays if you’re programming several projects a day.”

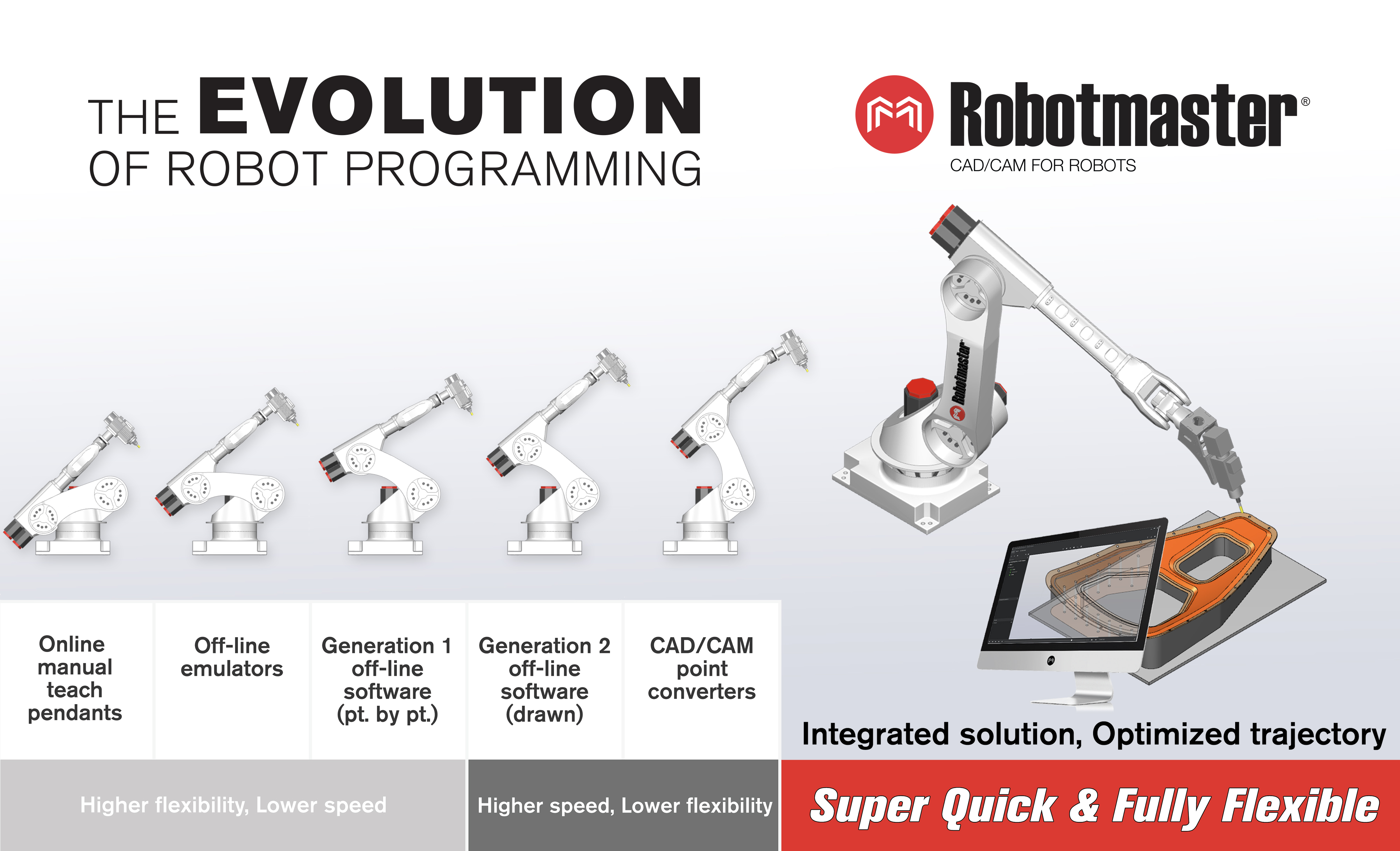

Rewriting the Evolution of Robot Programming

In the early days of robot programming a high level of robotics expertise was necessary. Manual teach pendants were used online, delaying production. Eventually offline emulators were created with simulation packages which simply migrated the same concept to an offline environment.

As offline programming software advanced, the first generation of CAD-based tools emerged. These early robot programming methods were extremely slow, although they offered a much higher level of flexibility.

The second generation allowed the software user to draw a trajectory, or curve, and then calculate the best way to get from point A to point B. As the process became more automated, programming time was reduced at the expense of flexibility. With the progression to CAD/CAM point converters, the speed increased however the software still required CAD and robotics expertise. Popular offline programming tools continued to be built on machining ideals and piggybacked on CAD/CAM software.

It was time for a radical change. A disruptive, new architecture was designed with the robotics user in mind.

Integrated Solution With a User-Centric Design

Taking what they learned from two decades of creating award-winning offline programming software, the Robotmaster team started over to create the ultimate software interface that anybody could use. Developers created a new integrated solution to optimize robot trajectories quickly, while maintaining flexibility.

“We wanted to create a new breed of CAD/CAM tools very specific to robotic applications, says Cakmak. “A major difference is that it’s intuitive, automated task-based programming.”

The launch of Robotmaster V7 offline programming software marks a revolution in the future of robot programming. For the first time, robotic automation will be just as practical for the everyday manufacturer as it is for high-volume users of robotics. Intuitive programming tools now cater to the process expert.

“We expect an end user to know and understand their task and process. Our software helps them program the robot without acquiring significant expertise in programming, CAD/CAM or robotics,” says Cakmak. “Once the process expert wants to trim an edge, error free results are generated.”

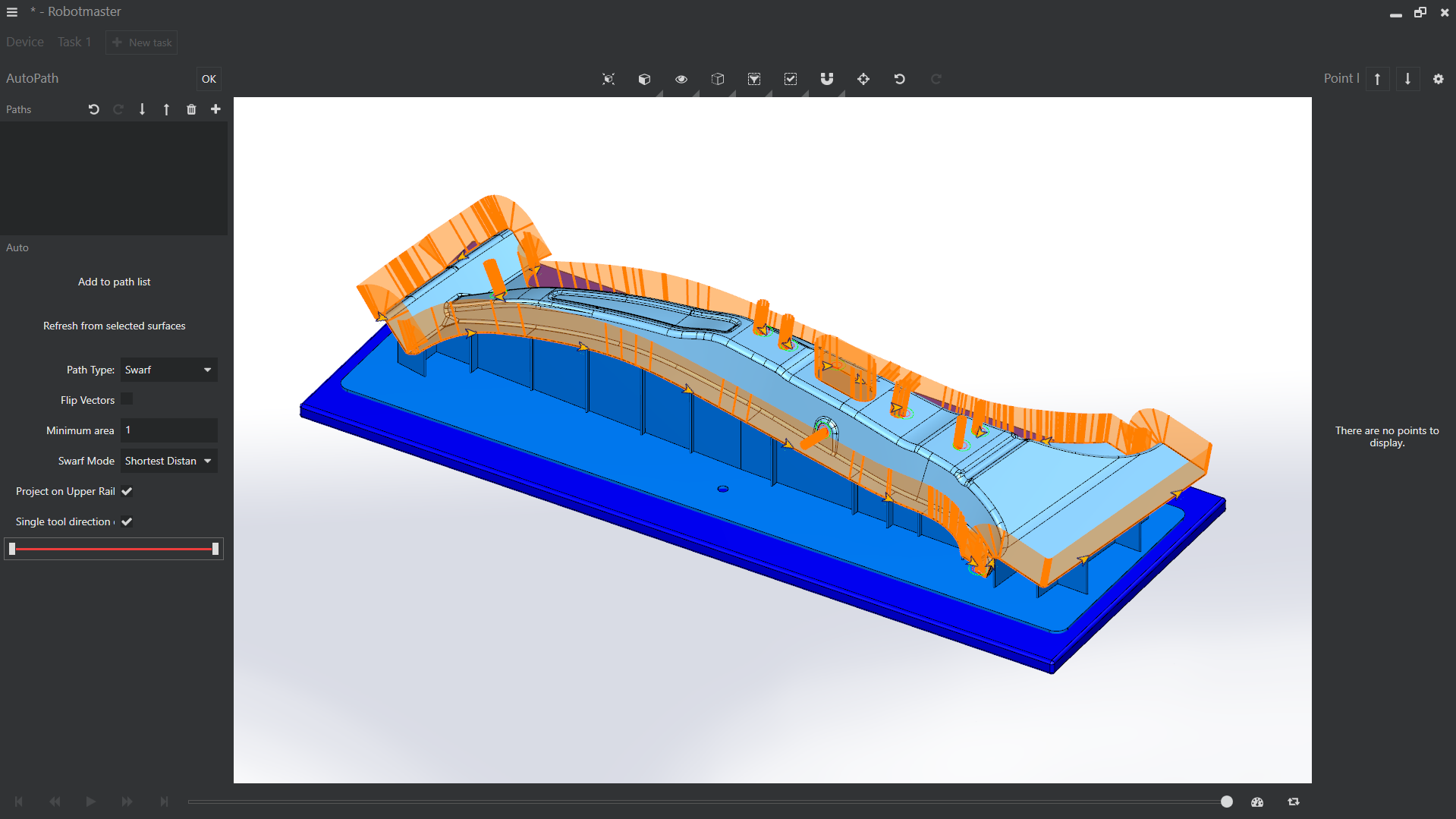

The software automatically analyzes and preprocesses imported CAD models. The intuitive interface then prompts users for a few simple settings related to their particular task, and the software performs all the necessary calculations.

“In one click, we’ve taken 5 to 10 minutes of an expert CAD/CAM user’s time to be able to create all of these points and lines,” says Cakmak. “With one click, the robot path is created.”

The integrated path programming tools include intuitive graphical interaction and robot path preview. Users also have access to specific robot functions including speed settings, motion optimization and powerful transition tools. The task-based interface enables users to see how different robotic variables will impact their process.

“Complexities such as singularity, reach issues, joint limits and collisions are very abstract to someone that has no robotics expertise,” says Cakmak. “Our software is able to manage these complexities in an automated way.”

Harnessing the Power of Robot Flexibility

One of the greatest strengths of robotics is also a significant challenge. By design, a six-axis robot is extraordinarily flexible.

As traditional processes became more complex, the five-axis machine eventually emerged, but still had no redundancy. For a particular task, there was only one way to orient the tool in order to manufacture that part.

Then along came robotics. At any given point, a task can range from two to five degrees of freedom, but a robot has a minimum of six degrees of freedom. There is no longer a one-to-one relationship between the task dimensions and the axes on the machine; in this case the robot. Now you have a robot that is overdetermined for the task. That flexibility has to be harnessed.

“When we speak to robot manufacturers and integrators, they often revel in all the robot can do,” says Cakmak. “But what’s holding them back is the lack of software tools to allow an end user to take all that flexibility and be able to harness it without being an expert in the field.”

Harnessing that flexibility poses challenges. The additional degree of freedom most common in the robot is the rotation around the tool. This rotation is independent of the task, meaning for most applications, it does not directly impact the orientation of the tool to the part. Hence, you have redundancy.

In addition to this redundancy, a typical six-axis robot has eight possible configurations for every programmed point. These configurations cause another major issue for programming, which is singularities.

Simplifying Singularities

A singularity is an undesirable phenomenon that occurs when at a specific point there is no single solution for the upcoming robotic movement, and because of this mathematical ambiguity the robot can not continue the task.

Singularity is a major issue in robotics because a typical six-axis robot has three potential “areas of singularity”: the wrist, the elbow and the base. When two joints are parallel to each other, the alignment causes this mathematical ambiguity. As the robot approaches singularity, there is a lot of acceleration and excessive speed in certain robot joints. As a result, the quality of the robot path deteriorates significantly or the robot stops, and an error message appears.

When programming a robot, not only are there these types of complexities surrounding the mechanism of the robot itself with its additional degree of freedom, but also varied applications.

“It’s like the Wild West when it comes to the great variety of applications we have to cater to,” says Cakmak. “We’re no longer dealing with a dedicated machine tool.”

The greater the number of tasks performed in each cell, and with multiple-robot cells, the higher the potential for singularities, reach issues, joint limits and collisions to occur. Without the right software tools for simulation and optimization, it’s very difficult to avoid these issues. It would be analogous to choosing the best route to take to arrive somewhere distant without the benefit of electronic map-routing...or a GPS. These tools allow for a macro-level view to optimize the task.

Integrated CAD/CAM Tools for the Non-Programming-Expert

The initial release of Robotmaster V7 software addresses a single six-axis robot with the option of external axes such as rails or rotary tables. Further software versions will support automated programming features for multi-robot cells and seven-axis robots.

Users can immediately take advantage of the integrated CAD/CAM functionality of Robotmaster V7 software for simple applications like welding and contouring, including trimming, cutting and deburring. These integrated CAD/CAM tools are specifically designed for robotics instead of CNC machining, and with the non-technical robotic user in mind. CAD/CAM jargon is replaced with easy-to-understand terms and intuitive menus.

Users can now also import paths from any CAD/CAM software. Subsequent software releases will incorporate software bridges to allow existing users of Robotmaster software to leverage their own CAD/CAM tool of choice. The software bridges will enable automated bidirectional data sharing between Robotmaster software and a growing portfolio of popular CAD/CAM systems, including CNC Software’s Mastercam platform, Dassault Systèmes CATIA and Siemens NX software.

Robotmaster V7 Software has Altered the Evolution of Robot Programming

Robotmaster harnesses the robot’s remarkable flexibility with an integrated solution that is quick and simple to use, but so robust as to manage complex robotic cells. With just a few clicks in the intuitive interface, error-free results are achieved by task and process experts who have never before used robotic programming software. These advances are so disruptive that only the development of a new architecture could have accomplished them. It automates task-based programming for first-time robot users and experienced integrators alike. A new paradigm to finally leverage and empower the full capabilities of robots.