In the world of robotics, Offline Programming (OLP) has come a long way in a short time, and the global pandemic has jumpstarted more innovation. Industrial robots have evolved from complex assembly line robots to collaborative robots (“cobots”) that work side by side with their human counterparts. As technology advances, the industry is seeing many changes and enhancements to OLP.

Previously we examined trends such as versatility and smart machines and how they are impacting the robotics and OLP world. In this article, we will examine the importance of simplicity, accessibility, and simulation capabilities.

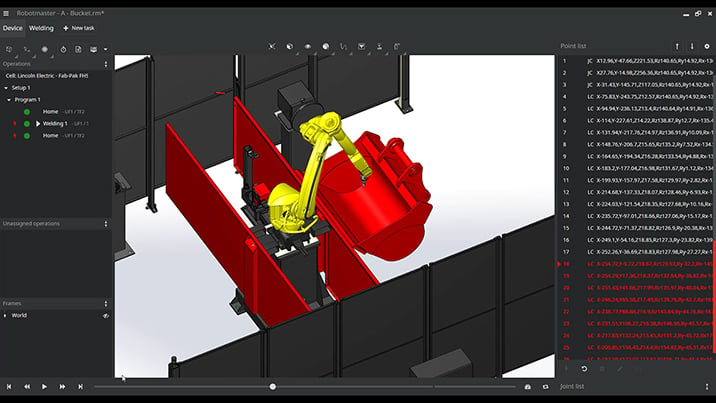

There are a few OLP solutions in the market, each with varying strengths. Robotmaster® offline programming software has always strived to create a powerful robot programming solution while being as user-friendly as possible. Each software element needs a purpose, and users should be able to approach and use it confidently, regardless of their robotics experience level. Users do not need to be a robotic or CAD/CAM expert to utilize OLP software.

One way to provide a positive user experience has been through the use of open/flexible architecture, which allows users to have the best of both worlds, providing the advantage of the standard features, while allowing some of the functionality to be customized to meet their unique challenges.

One of the advantages of OLP and CAD is building, testing, tweaking, and training a robot virtually, before it is installed in the factory. Advances in augmented and virtual reality will continue to push the envelope, and OLP will need to keep pace. Singularities and joint limits can be identified and solved in the simulation environment before the robot is installed. Areas prone to kinematic errors can be anticipated and optimized in engineering the robot cell prior to installation.

Users will continue to push for enhancements such as a user interface that provides graphical feedback to the programmer. Real-time data is key to answer common questions like, “Is the robotic path good to execute,” or “Why have I encountered path issues like singularities and collisions, or come across reach limits requiring edits to be performed?”

The more calibration that can be done before installation, the faster and more efficiently the robot integration can be completed and up and running.

Want to learn more about OLP? Check out About Offline Programming for robots.

Robotmaster®, a Hypertherm brand, is an offline programming software for robots that helps manufacturers maximize productivity on production runs of all sizes. Robotmaster makes programming parts of any complexity quick and easy as a result of its integrated CAD/CAM functionality. This intuitive and powerful solution is designed with process experts in mind reducing the need for programmers and robotic expertise.