In the world of robotics, Offline Programming (OLP) has come a long way in a short time, and the global pandemic has jumpstarted more innovation. Industrial robots have evolved from complex assembly line robots to collaborative robots (“cobots”) that work side by side with their human counterparts. As technology advances, the industry is seeing many changes and enhancements to OLP.

The first future trend we will examine is versality.

When manufacturing facilities first started to use robots, the robots were massive, cumbersome, and task specific. One robot did the welding, another the grinding, and another the assembly. Repairing, updating, and resetting required significant production downtime, and the robots needed a large footprint to operate safely. They were costly, required skilled technicians to operate them, and were often out of reach for small and mid-sized manufacturing operations. Robots were chosen for the task, and it was not uncommon to have several different robot brands within the same manufacturing operation. That required programmers to be versed in several different programming languages, which complicated training, parts management, maintenance, and software updates.

Companies wanted an all-in-one solution that could integrate with existing hardware. Rather than a series of piecemealed solutions to get the ideal setup, manufacturers and integrators sought out an integrated solution that works with various applications, especially in a high-mix, low-volume operation. This is where Offline Programming (OLP) software originated. When properly designed, OLP software can communicate to any robot brand, even older models, making the robot cell more flexible, and able to switch tasks without production downtime. As advancements in machine learning, artificial intelligence (AI), and the Industrial Internet of Things (IIoT) continue to push the capabilities of manufacturing technology, OLP software will continue to simplify and integrate robotic solutions. Companies that want to expand into new product areas can use OLP for programming, path creation, simulation, optimization, and validation.

Flexible OLP software allows companies to customize a solution that incorporates specific elements unique to the manufacturing facility, while taking advantage of the knowledge of others who have come before. This trend of collective wisdom is likely to continue.

Want to learn more about OLP? Check out About Offline Programming for robots.

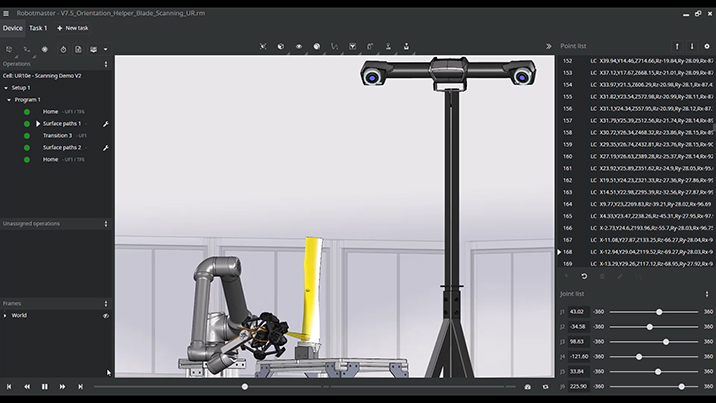

Robotmaster®, a Hypertherm brand, is an offline programming software for robots that helps manufacturers maximize productivity on production runs of all sizes. Robotmaster makes programming parts of any complexity quick and easy as a result of its integrated CAD/CAM functionality. This intuitive and powerful solution is designed with process experts in mind reducing the need for programmers and robotic expertise.