Another Leap Forward in the Revolution of Robotic Programming

Robotmaster Version 7.1 is now out!

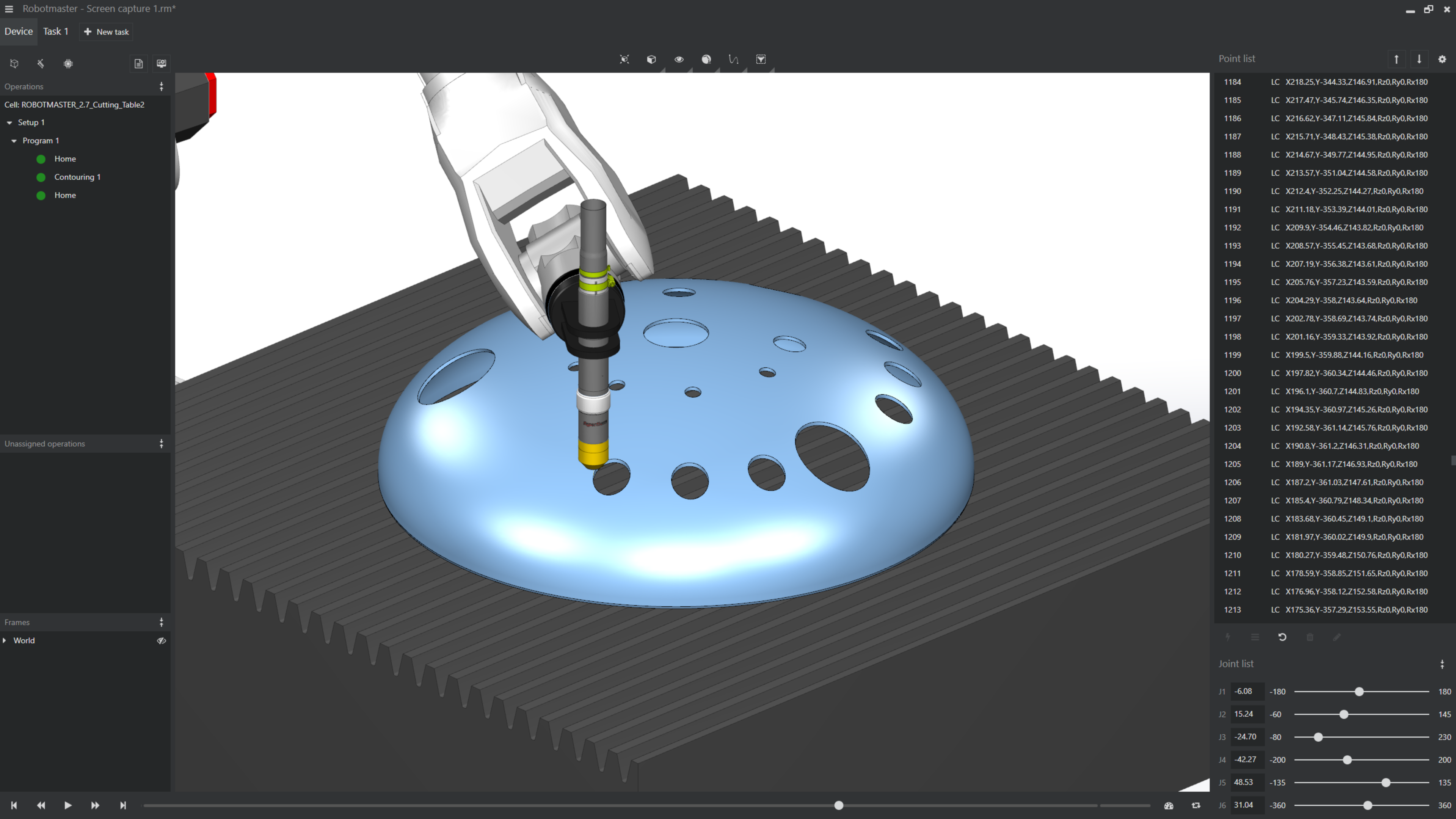

Montreal, Canada- August 15, 2019 - The release of Robotmaster Version 7 in 2018 revolutionized the offline robot programming industry. Simple to complex robotic tasks, from a straightforward plasma cutting job, to deburring and additive manufacturing applications, error-free task-based programming is just a click away. Our goal was to create software so advanced anyone can use it. Our strong background in CAD/CAM (Computer Aided Manufacturing) software enabled us to bring a revolutionary approach to programming industrial robots.

Over the past year, we’ve listened to your feedback and have implemented more than 40 new features, made over 500 improvements, and fixed our fair share of bugs (yes like all software, we admit to having our share of bugs). All these new changes are now available in our latest major software update, Robotmaster Version 7.1!

Working from the completely redesigned and advanced architecture of Version 7, the robotic software team at Hypertherm continues to rewrite the revolution of robot programming. From continually improving the state-of-the-art proprietary CAM (path creation) technology inside of Robotmaster, to automated programing by using the best error-free path for your robot in just one click- Robotmaster's new software update makes it that much easier to let the task expert focus on their job with no robotic expertise required.

Say goodbye to manually teaching your robot or using simulation software that doesn't take collisions, singularities, joint collisions and any other robotic error into account before you run the program live on your robot! How? While your robot is working on a job, you're programming new parts in Robotmaster without interrupting the robot, and all that is left is to automatically upload the new optimized programs to your robot. This eliminates any downtime and instantly increases your productivity and profitability.

Today, Robotmaster software is running on robots drilling airplane fuselages at Boeing and Airbus, polishing automotive dies at Daimler Mercedes, and adding value to a multitude of processes at family-owned job shops around the world.

Join the revolution of robot programming!