Jabez Technologies has just released Robotmaster V6.1

Jabez Technologies has just released Robotmaster V6.1. Building on the Robotmaster Interactive Simulations Environment introduced in 2013, V6.1 provides exciting new features and enhancements developed specifically for high-mix low-volume robotic applications. V6.1 has been designed to further elevate programming productivity, supporting an ever increasing array of robot brands and applications.

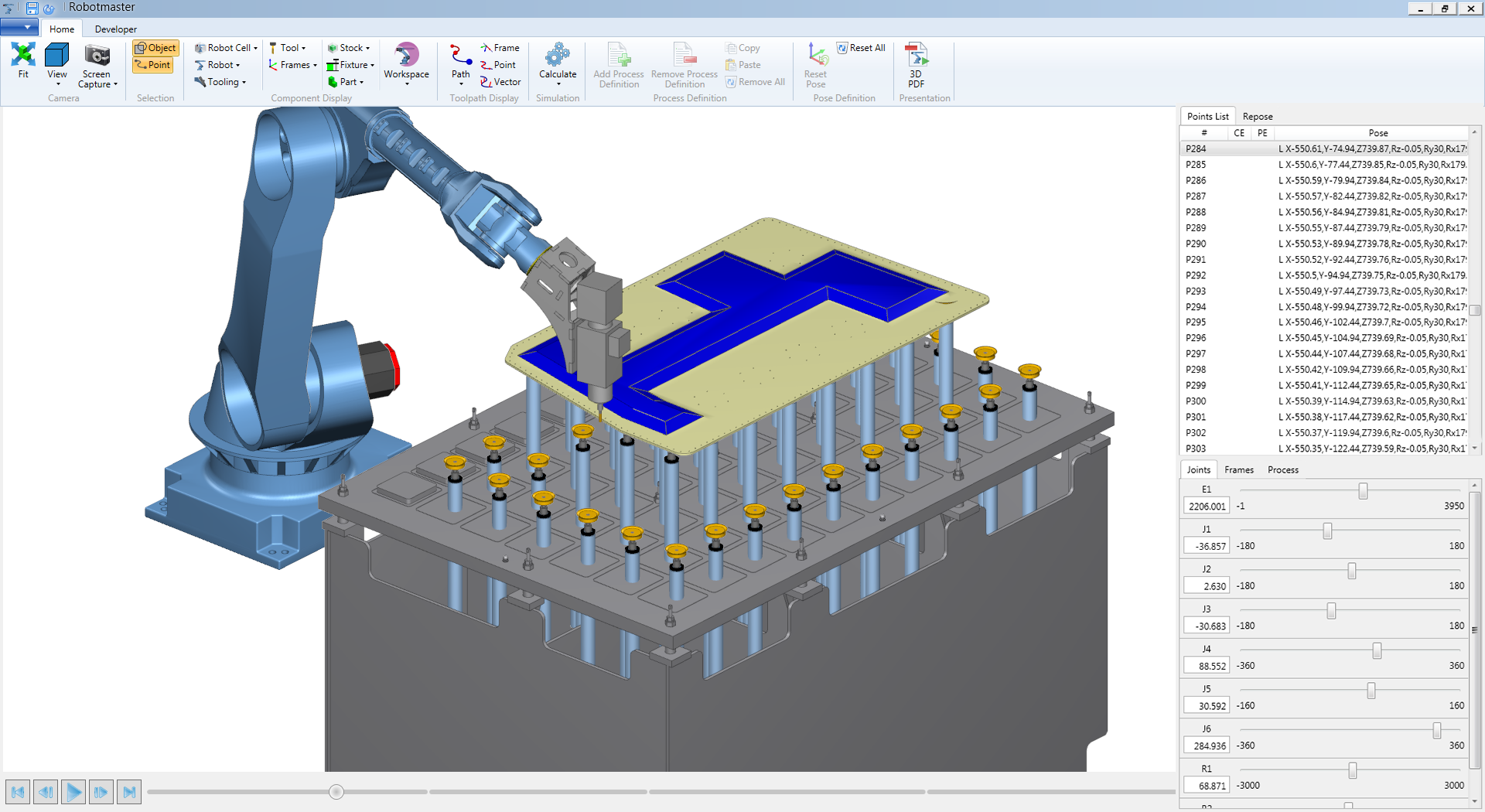

Enhanced process control and simulation

The increasing demands for flexible automation using robots are producing innovative and configurable tooling which can carry out one or several manufacturing processes. The Robotmaster Interactive Simulations Environment (RISE) has been expanded to support the demands of these applications which require precise control of all process parameters with direct validation of the programming during simulation. A new script language has been implemented which can be used in conjunction with an application’s process settings to customize simulation behavior. Custom tooling and devices with simple to complex behavior and motion can quickly and seamlessly be verified in the same simulation environment used to validate the robot programming. Enhancements to user control include multi-point editing and accessing simulation from anywhere in Robotmaster. New features and performance enhancements have been added to 3D-PDF file creation, further facilitating the sharing of simulation and programing results.

## Robot brand support

As robots and their programming languages evolve, V6.1 includes the latest enhancements to easily exploit the full potential of each robot brand. We have been working closely with all major robot manufacturers to ensure that our support for their robots is current and comprehensive. New robot brands supported for V6.1 include OTC/Daihen and Kawasaki with significant enhancements made for ABB, Fanuc, Kuka, Motoman and Staubli.'

## Cutting

Users can quickly create optimized paths for plasma, water-jet and laser cutting with ultimate control of their robot for error-free programs. All cutting parameters can effectively be controlled with new process screens which are customizable and fully integrated inside Robotmaster.

## Welding

Simple to complex welds can easily be programmed using “one-click” automatic seam programming. Automated strategies for entry/exit, corner settings, push/pull angle and stitching in addition to full manual control provide an ideal combination of quick programming and ultimate flexibility. Users can quickly program successful welding paths through instant visualization of the impact of any changes in the path, torch angle, reach or collisions. Robots mounted on rotary booms/arms can effectively be controlled in a variety of configurations with full flexibility. Welding parameters can easily be controlled with customizable screens for basic arc welding, multi-passes, seam tracking, weaving and touch sensing. Comprehensive arc welding support is available for Yaskawa Motoman, ABB (ArcWare), OTC/Daihen, Fanuc and Kawasaki robots with ongoing development for Kuka and Panasonic brands.

## Composites

The increased adoption of composites (including carbon-fiber) in manufacturing creates new requirements for robot programming and several new features have been introduced in V6.1 to offer productivity including:

## Robot brand support

As robots and their programming languages evolve, V6.1 includes the latest enhancements to easily exploit the full potential of each robot brand. We have been working closely with all major robot manufacturers to ensure that our support for their robots is current and comprehensive. New robot brands supported for V6.1 include OTC/Daihen and Kawasaki with significant enhancements made for ABB, Fanuc, Kuka, Motoman and Staubli.'

## Cutting

Users can quickly create optimized paths for plasma, water-jet and laser cutting with ultimate control of their robot for error-free programs. All cutting parameters can effectively be controlled with new process screens which are customizable and fully integrated inside Robotmaster.

## Welding

Simple to complex welds can easily be programmed using “one-click” automatic seam programming. Automated strategies for entry/exit, corner settings, push/pull angle and stitching in addition to full manual control provide an ideal combination of quick programming and ultimate flexibility. Users can quickly program successful welding paths through instant visualization of the impact of any changes in the path, torch angle, reach or collisions. Robots mounted on rotary booms/arms can effectively be controlled in a variety of configurations with full flexibility. Welding parameters can easily be controlled with customizable screens for basic arc welding, multi-passes, seam tracking, weaving and touch sensing. Comprehensive arc welding support is available for Yaskawa Motoman, ABB (ArcWare), OTC/Daihen, Fanuc and Kawasaki robots with ongoing development for Kuka and Panasonic brands.

## Composites

The increased adoption of composites (including carbon-fiber) in manufacturing creates new requirements for robot programming and several new features have been introduced in V6.1 to offer productivity including:

- Automated and flexible trimming using intelligent analysis tools;

- Comprehensive support for simple to complex drilling and riveting;

- Easy configuration and programming of Universal Holding Fixtures (UHF);

- Automated fixture creation with one click design/creation of trimming jigs;

- Introduction of new tools for fiber tape lay-up programming.

Robotmaster continues to enhance the robot programing experience; with its intuitive and dynamic software tools, V6.1 allows users to quickly achieve desired control and program success through an ever expanding variety of applications and robot brands.