Saravanan Rajaram, Mechanical Engineering

McStarlite

Automation is something we had been wanting to do for over a decade...automation standardizes the finish, the consistency, and improves our cycle time.”

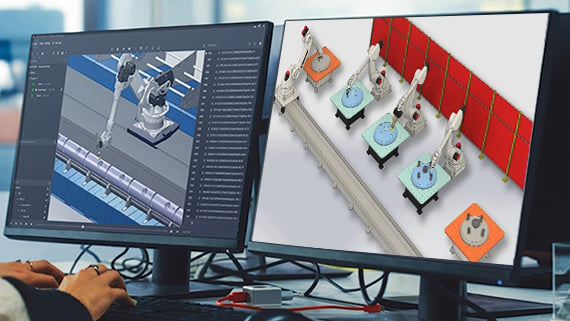

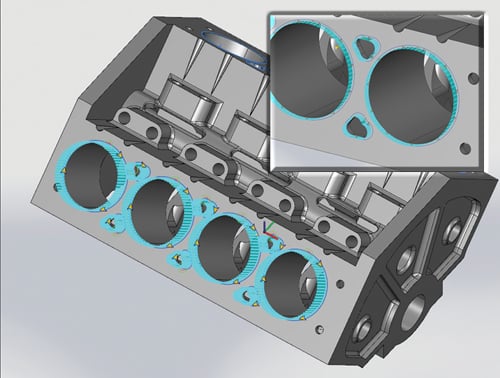

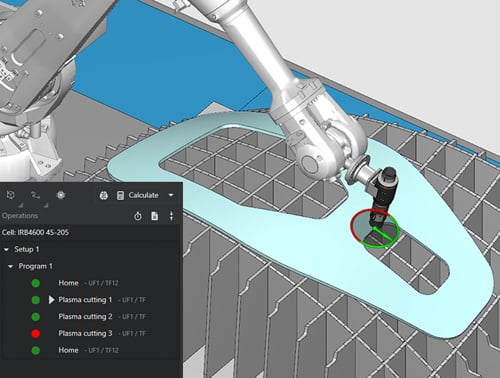

Robotmaster® is an offline programming software for industrial robots that seamlessly integrates cell layout and planning, CAD to path programming, program optimization, simulation and code generation. Robotmaster is a powerful and easy-to-use robot programming method ideal for:

Programming high-mix, low-volume production

Automating complex shape processes

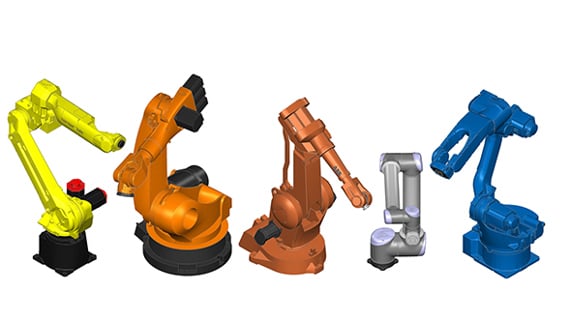

Programming a variety of robot brands

Increasing efficiency and lowering costs

Users with minimal to no programming and robotics expertise

Robotmaster blends powerful tools, essential for programming complex applications and shapes, with intelligent and intuitive features enabling users of all experience levels to program with confidence.

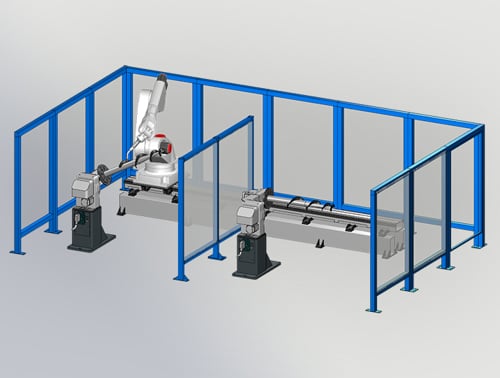

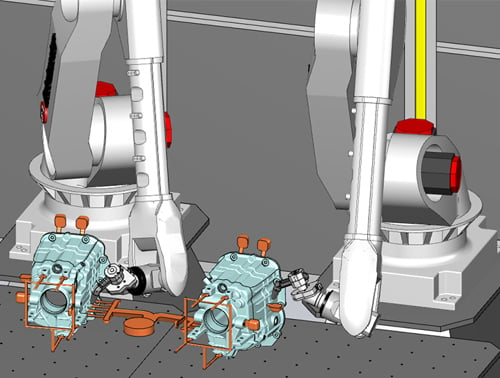

Program robotic systems with multiple robot arms and/or external axes including rails and rotaries with Robotmaster’s powerful programming tools.

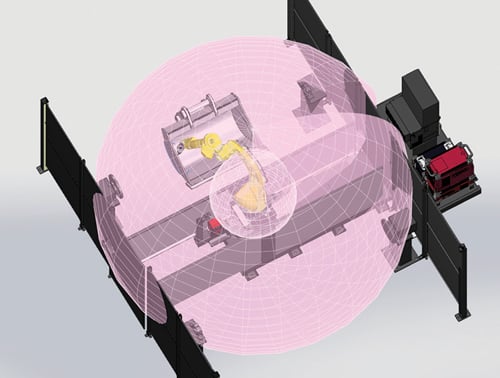

Create a virtual model of the robotic system and its environment to visualize and plan movement and tasks prior to deployment.

Programming robots using OLP software allows them to stay in production around the clock. Leverage path planning and program distribution tools to ensure you achieve low cycle times and boost output.

Intelligent pathing modules to handle industry leading robotic applications without requiring CAD/CAM skills.

Single-click path optimization and error-correction tools to ensure optimal cycle times are achieved and collisions are avoided.

Bridge the gap between CAD/CAM and robotics with embedded technology to seamlessly translate CAD/CAM trajectories into robot trajectories.

Robotmaster offline programming (OLP) software for robots supports a variety of robot brands such as ABB, FANUC Robotics, KUKA, YASKAWA Motoman, Universal Robots, and more.

Robot brand support may vary by application. Please contact us to see if your brand is supported.