What is Robotmaster

Robotmaster CAD/CAM for robots seamlessly integrates off-line programming, simulation and code generation, delivering quick, error-free robot programs.

- accurate robot trajectories without teaching points

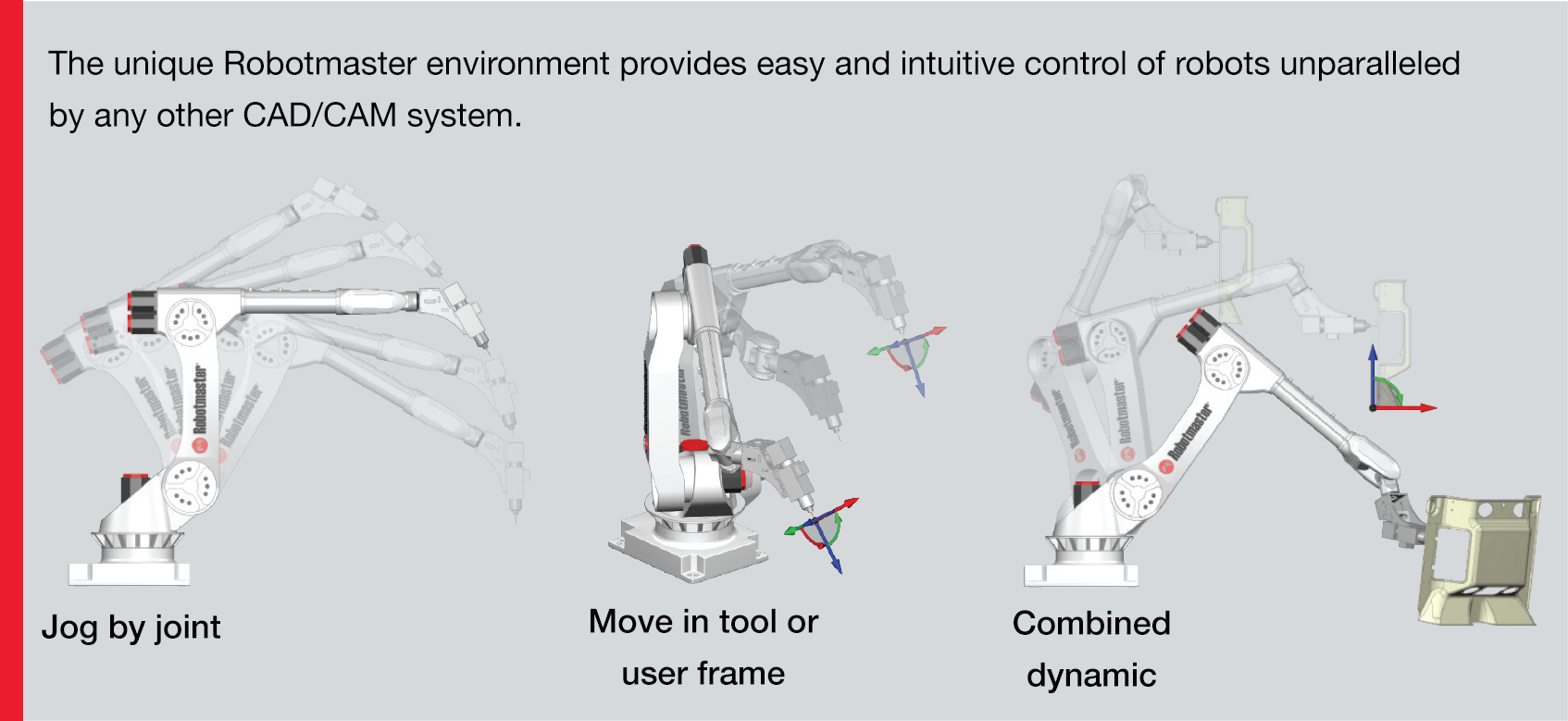

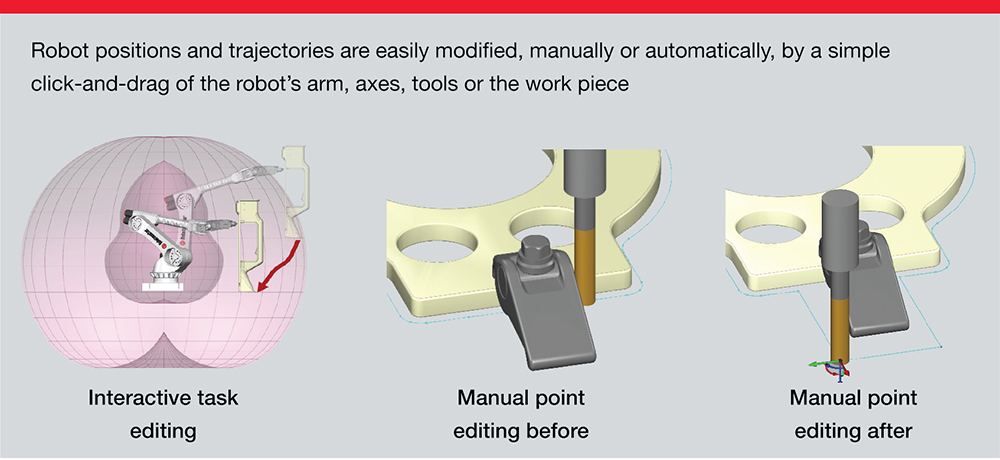

- “click-and-drag” interactive simulation/editing environment

- automated robot motion optimization

- multiple robot manufacturers compatibility

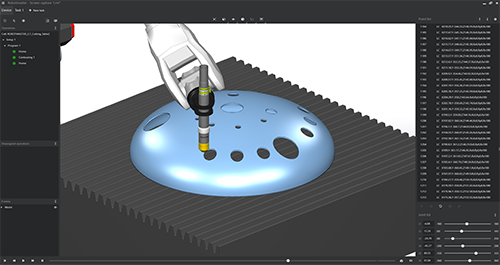

Interactive Simulation Environment

Robotmaster helps manufacturers use robots to produce higher quality products at lower cost, with the speed and flexibility needed to challenge competitors around the world.

Singularity, calibration, collisions, reach limitations, and motion granularity are uniquely complex to robotic systems and can make programming particularly cumbersome. Robotmaster’s Interactive Simulation Environment (RISE) provides a unique tool for programming, visualizing and optimizing processes/events quickly and easily.

Main Features

Optimization

Robotmaster gives rapid visualisation of issues and opportunities to easily obtain optimal robot programs. Its full interactivity makes it the comprehensive tool to find the best solution, without point-by-point intervention, even through a narrow band of opportunity. Instead of the usual frustrating hit-and-miss approach, quickly create error-free programs, without possessing highly specialised robotic knowledge.

- All errors are visualized and mapped in a single screen and color coded by type

- Full set of all possible solutions is generated and ranked based on user selected criteria

- A few clicks in the error screen adjust the paths correcting all problems

- Ability to optimize multiple parameters simultaneously including: tool rotation, tool tilt and rail & rotary positions

Workspace Analysis

Click-and-drag simplicity to solve robot reach and work piece positioning issues with real-time visualization and validation – an essential tool for exploring work cell configuration and defining optimum positioning of the work piece.

- Easy visualisation of the task space required by all operations superimposed over the work cell boundaries

- Click and drag to re-position and/or re-orient the workpiece with dynamic feedback showing the full impact of changes made on all operations

Transitions Manager

Robotmaster easily programs collision-free transitions that minimize cycle time between operations.

- Robotmaster automates the onerous task of moving the robot joint-by-joint to create safe transition paths

- Automated and semi-automated interactive tool set to eliminate errors and collisions

- Optimizes the robot posture and configuration automatically to successfully perform the next task

6-axis Contouring

Powerful, integrated 6-axis contour programing empowers the process expert to create optimised programs without having to learn complex CAD/CAM and intricate robot simulation skills.

- One-click contour identification and programming even on complex edges and for any CAD model

- Easy and extensive contour editing capabilities, without requiring CAD/CAM skills

- Ability to dynamically edit the path to change the tool position and orientation

- Powerful, best-in-class contour creation specifically designed for robot programming

External axis management

With Robotmaster, the entire robotic cell including all external axes is managed as one integrated system- effortlessly control the motion of all axes, including rails and rotaries, to fully exploit and optimize processing of even the largest and most complex work pieces.

- Ability to index external axes and/or program them for fully coordinated motion

- Combined, simultaneous coordination of external axes for ideal tool orientation

- The full power of Robotmaster optimization to control all external axes.

Custom process definition

Robotmaster speaks your process language - streamlined, application-specific user interfaces that allow the process expert to set and manage his optimal parameters.

- The integration of parameters specific to the user’s process (e.g. welding, cutting, etc.) is simplified with the modifiable screens that define the interaction, terminology and control setting unique to the application

- The process parameters can be created, modified and fully controlled by the user for the entire program, specific operations or at select points